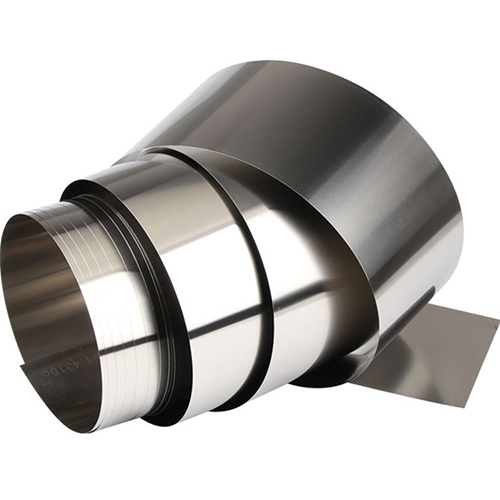

I-Titanium strip, i-titanium foil ehlanzekile kakhulu

I-Titanium strip,ukuhlanzeka okuphezulu kwe-titanium foil,

Ibanga lesi-2, Ibanga lesi-5, Ibanga lesi-7 nele-9, Ibanga, ukuhlanzeka okuphezulu kwe-titanium foil, I-titanium yezokwelapha, I-Titanium Strip, I-Tittanium Strip kanye ne-Foil Materials: I-Pure Titanium(CP) ne-Titanium alloy foil,

• I-Tittanium Strip ne-Foil Materials: I-Titanium ehlanzekile (CP) ne-Titanium alloy foil, i-Grade1,Ibanga lesi-2, Ibanga lesi-5, Ibanga lesi-5,Ibanga lesi-7 nele-9

• Amafomu: I-strip eyodwa, ikhoyili, noma ku-spool.Isevisi yokusika iyatholakala

• Ubukhulu:Ubukhulu: ≥0.01mm : 20~1000mm, Ubude: Njengesicelo

• Izimo:Okugoqiwe okubandayo(Y)~I-Hot rolled(R)~I-Annealed (M)~Isimo Esiqinile

• Amazinga:ASTM B265, AMS 4911, AMS 4902, ASTM F67, ASTM F136 njll

• Izinhlelo zokusebenza:Ama-elekthronikhi, amakhemikhali, amawashi, izibuko, ubucwebe, izimpahla zemidlalo, imishini, okokusebenza okucwebezelayo, okokusebenza kwezemvelo, igalofu kanye nezimboni zemishini yokunemba.

| I-Titanium Alloys Material Igama Elivamile | ||

| Gr1 | I-UNS R50250 | I-CP-Ti |

| Gr2 | UNS R50400 | I-CP-Ti |

| Gr4 | I-UNS R50700 | I-CP-Ti |

| Gr7 | I-UNS R52400 | I-Ti-0.20Pd |

| G9 | I-UNS R56320 | I-Ti-3AL-2.5V |

| G11 | I-UNS R52250 | I-Ti-0.15Pd |

| G12 | I-UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | I-UNS R52402 | I-Ti-0.05Pd |

| G23 | I-UNS R56407 | Ti-6Al-4V ELI |

I-Titanium Stripkanye ne-Foil:Sinikeza ikakhulukazi i-titanium Strip ehlanzekile ye-Gr1, Gr2, Gr4 amamaki;Nge-titanium alloy Foil, Sihlinzeka ngokuyinhloko nge-Gr5, Gr7, Gr9, Gr11, Gr12, Gr16, Gr23 namanye amabanga,Akhiqizwa ngesisekelo sepuleti le-titanium elinokugoqeka okubandayo;inqubo yokukhiqiza ye-titanium sheet iyinkimbinkimbi kakhulu.Ukulawulwa kwe-deformation kuqinile kakhulu ohlelweni lokugoqa.Lokho kungasikwa ngamasayizi ahlukene ngokuya ngezidingo zekhasimende, kufinyeze kakhulu isikhathi sokulethwa.

♦ Ukwakheka kwe-Titanium Strip Chemical ♦

| Ibanga | Ukwakheka kwamakhemikhali, iphesenti lesisindo (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Ezinye Izinto Ubukhulu.ngamunye | Ezinye Izinto Ubukhulu.ingqikithi | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5 6.75 | 3.5 4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 0.25 | - | 0.12 0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | - | - | - | - | 0.1 | 0.1 |

♦ Titanum Alloy Strip Physical properties♦

| Ibanga | Izici ezingokomzimba | |||||||

| Amandla aqinile Okuncane | Amandla e-Ield Min (0.2%, offset) | I-Elongation ku-4D Ubuncane (%) | Ukuncishiswa Kwendawo Ubuncane (%) | Ukuhlolwa kwe-Bend(Radius of Mandrel) | ||||

| ksi | I-MPa | ksi | I-MPa | <1.8mm Ebugqileni | 1.8-4.8mm Ubukhulu | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 | 1.5T | 2.0T |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 | 2.5T | 3.0T |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 | 4.5T | 5.0T |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 | 2.5T | 3.0T |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 | 1.5T | 2.0T |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 | 2.0T | 2.5T |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 | 4.5T | 5.0T |

♦ ♦ ♦ Titanium Alloy Materials Izici: ♦ ♦ ♦

•Ibanga loku-1: I-Titanium ehlanzekile, amandla aphansi uma kuqhathaniswa kanye ne-ductility ephezulu.

•Ibanga lesi-2: I-titanium emsulwa esetshenziswa kakhulu.Inhlanganisela engcono kakhulu yamandla

•Ibanga lesi-3: I-Titanium enamandla amakhulu, isetshenziselwa amapuleti e-Matrix kumagobolondo nezishintshi zokushisa zamashubhu

•Ibanga lesi-5: Ingxubevange ye-titanium ekhiqizwa kakhulu.Amandla aphezulu ngokwedlulele.ukumelana nokushisa okuphezulu.

•Ibanga lesi-7: Ukumelana nokugqwala okuphezulu ekwehliseni nasekufakeni oxidizing izindawo.

•Ibanga lesi-9: Amandla aphezulu kakhulu kanye nokumelana nokugqwala.

•Ibanga le-12: Ukumelana nokushisa okungcono kune-Titanium emsulwa.Izicelo zeBanga lesi-7 nele-11.

•Ibanga lesi-23: I-Titanium-6Aluminium-4Vanadium ELI (I-Interstitial Ephansi Engeziwe) Ingxubevange yokufakwa kokuhlinzwa kokufakelwa.

I-Sekonic Metals Technology Co., Ltd ihlinzeka ngepuleti le-titanium, i-titanium rod, i-titanium capillary, i-titanium screw, i-titanium fastener, induku yocingo ye-titanium, i-titanium nut, izingxenye ezimise okwezimo...Sizibophezele ekunikezeni amakhasimende ethu imikhiqizo/izinkonzo ezisezingeni eliphezulu, uma uthanda imikhiqizo namasevisi sicela usithinte, sibheke ngabomvu impendulo yakho