Ithagethi ye-Titanium Plate

Ithagethi ye-Titanium:Sisebenzisa i-titanium alloy billet, noma ipuleti ukuze lifakwe ngomshini i-titanium targets.Okuqukethwe ukungcola kwe-industrial pure titanium kungaphezu kwalokho kwekhemikhali ye-titanium emsulwa, ngakho amandla ayo kanye nobulukhuni bayo buphakeme kancane.Izakhiwo zayo zemishini namakhemikhali ziyafana nalezo zensimbi engagqwali.Uma kuqhathaniswa ne-titanium alloy, i-titanium emsulwa inamandla angcono futhi inokumelana ne-oxidation okungcono.Ingcono kune-austenitic stainless steel, kodwa ukumelana nokushisa kwayo kubi.I-TA1, i-TA2, i-TA3 ukwanda kokuqukethwe ukungcola, amandla emishini nobulukhuni bukhuphuka ngokulandelana, kodwa ukuqina kwepulasitiki kuncipha ngokulandelana.

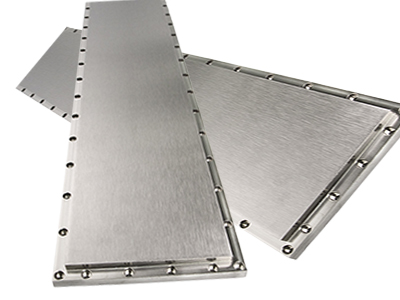

• Ithagethi ye-Tittanium Plate: Grade1, Grade 2, Grade 5, Grade 5, Grade7 , Grade9, Grade11, Grade12, Grade 16, Grade23 ect

• Izinhlobo:Ithagethi Eyindilinga, Ithagethi Yepayipi, Ithagethi Yepuleti.ect

• Ubukhulu:60/80/120(W)×6/8/12(T)×519/525/620(L) &60-800(W)×6-40(T)×600-2000(L)Ngokwezifiso

•Subuso:indawo ekhanyayo noma i-Acid pickling surface

• Izinhlelo zokusebenza: esetshenziswa kumadivayisi wokuhlukanisa ama-semiconductor, izibonisi zephaneli eyisicaba, amafilimu e-electrode okugcina, i-sputtering coating, i-workpiece surface coating, imboni yokuhlanganisa ingilazi, njll.

| I-Titanium Alloys Material Igama Elivamile | ||

| Gr1 | I-UNS R50250 | I-CP-Ti |

| Gr2 | UNS R50400 | I-CP-Ti |

| Gr4 | I-UNS R50700 | I-CP-Ti |

| Gr7 | I-UNS R52400 | I-Ti-0.20Pd |

| G9 | I-UNS R56320 | I-Ti-3AL-2.5V |

| G11 | I-UNS R52250 | I-Ti-0.15Pd |

| G12 | I-UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | I-UNS R52402 | I-Ti-0.05Pd |

| G23 | I-UNS R56407 | Ti-6Al-4V ELI |

♦ I-Titanium Alloys Chemical Composition ♦

| Ibanga | Ukwakheka kwamakhemikhali, iphesenti lesisindo (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Ezinye Izinto Ubukhulu.ngamunye | Ezinye Izinto Ubukhulu.ingqikithi | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.56.75 | 3.5 4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 0.25 | - | 0.12 0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | - | - | - | - | 0.1 | 0.1 |

♦I-Titanum AlloyIzakhiwo Zomzimba ♦

| Ibanga | Izici ezingokomzimba | |||||

| Amandla aqinile Okuncane | Amandla esivuno Ubuncane (0.2%,i-offset) | I-Elongation ku-4D Ubuncane (%) | Ukuncishiswa Kwendawo Ubuncane (%) | |||

| ksi | I-MPa | ksi | I-MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |