I-High Temperautre Spring Disc Disc Spring Wave Spring

High Temperature Spring:

Intwasahlobo iyingxenye yemishini esebenzisa ukunwebeka ukuze isebenze.Izingxenye ezenziwe ngezinto ezinwebekayo ziyawohloka ngaphansi kwesenzo samandla angaphandle, futhi zibuyela esimweni sazo sangempela ngemva kokukhipha amandla angaphandle.Ibuye isetshenziswe njenge "spring".Ngokuvamile eyenziwe spring steel.Izinhlobo zemithombo ziyinkimbinkimbi futhi zihlukahlukene.

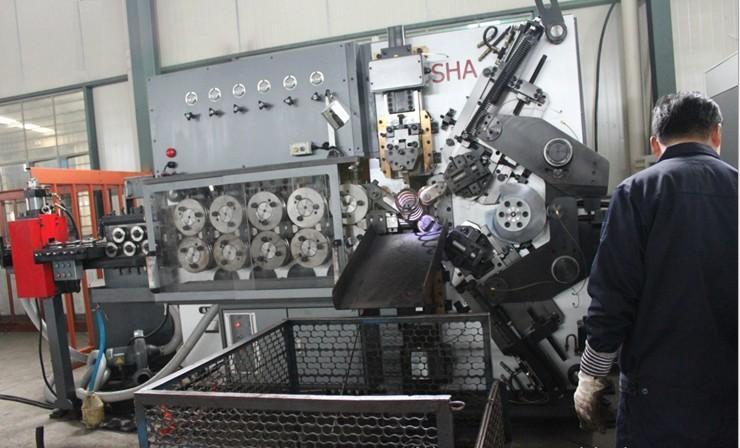

Inkampani Yethu Ehlangene Nezimboni Eziyinhloko Ze-Spring Factories futhi zihlinzeka ngama-Springs okushisa aphezulu

• Izisetshenziswa Zasentwasahlobo Zokushisa Okuphezulu:

I-SUS304,I-SUS316, SUS631/17-7PH, SUS632/15-7Mo, 50CrVA, 30W4Cr2VA,

I-Inconel X-750, Isilinganiso 718, I-Nimonic90, I-Incoloy A286(SUH660)

• Izinhlobo zasentwasahlobo:

→Imithombo Yokucindezela →Intwasahlobo yesandiso

→Intwasahlobo yeTorsion →Intwasahlobo egobayo

♦ Intwasahlobo ye-Wave ♦ SkrolaIntwasahlobo♦ I-Disc Spring

♦ I-Ring Spring ♦ I-Special-Shaped Spring, njll

| Izinhlobo Zezinto Ezibalulekile | Igama Lempahla | Izinga lokushisa eliphezulu Lokusebenza°C |

| insimbi engagqwali | SUS304/SUS316 | 200 |

| SUS631/17-7PH | 370 | |

| SUS632/15-7Mo | 470 | |

| I-alloy spring steel | 50CrVA | 300 |

| 30W4Cr2VA | 500 | |

| Izinga lokushisa eliphakeme le-nickel base alloy | I-Incoloy A286(GH2132) | 600 |

| I-Inconel X-750(GH4145) | 600 | |

| I-Inconel 718 (GH4169) | 690 | |

| I-Nimonic90(GH4090) | 800 (γ<0.2) | |

| GH4099 | 1000 (γ<0.1) |

♦♦♦ Ama-Disc Springs♦♦♦

Asetshenziswa kakhulu kuma-valve, ama-flange, ama-clutches, amabhuleki, iziguquli ze-torque, i-High-voltage switch, i-bolt tightening, ukwesekwa kwamapayipi, i-shockproof kanye nezinkambu ze-shockproof.bakhiqize ngokuhambisana ne-DIN EN16983 (DIN2093).

Ububanzi bangaphandle busukela ku-6mm kuye ku-1000mm.

Izinto zifaka phakathiingxubevange steel 51CrV4, carbon steel SK85, 1074;

• Insimbi engagqwali ASTM301, 304, 316, 17-7PH, 17-4PH, 15-7Mo;

• Insimbi ekwazi ukumelana nokushisa i-H13, X30WCrV53, X22CrMoV12-1, X39CrMo17-1;

• Insimbi engagqwali imelana nokushisa okuphezulu Inconel X750, Inconel X718, Nimonic 90, njll.

♦♦♦ Imithombo Yamagagasi♦♦♦

I-Wave spring iyingxenye yensimbi enwebekayo emise okwendandatho ezacile eyakhiwa amagagasi nezigodi ezimbalwa.Imithombo ye-Wave isetshenziswa kabanzi kumamotho, imishini yendwangu, imishini ye-hydraulic, izimoto nezinye izimboni.Ukufakwa okuyinhloko kanye nokucaciswa (usayizi ojwayelekile) wekamelo lokuthwala kufanelekile.Noma emgodini, indawo yokufaka incane, futhi inomsebenzi okhethekile wokunciphisa umsindo nokunciphisa ukudlidliza.

Ububanzi bangaphandle busukela ku-6mm kuye ku-1000mm.ububanzi busukela ku-0.4mm kuye ku-5.0mm.

Ukuvikelwa kokugqwala

- I-Phosphating

- I-Mechanical galvanizing

- I-Nickel plated

- Jiaomei

Banezici ze-deformation encane kanye nomthwalo omkhulu.Iphinde ibe nezici ezilandelayo.

- Ama-disc springs angathola izici ezihlukene zomthwalo ngokusebenzisa inhlanganisela ehlukene yokuguquguquka nokugqagqana.

- Uma kuqhathaniswa nezinye iziphethu, ama-disc springs athatha indawo encane.

- Lapho kusetshenziswa amashidi amaningi ngokuhlanganiswa, umphumela wokudambisa uyakhula.

- Uma isetshenziswe ngokunengqondo, ngeke ikhubazeke noma iphuke.

- Impilo ende yokukhathala.

| Izinto Zasentwasahlobo | Isikhathi Sokusebenza | Amandla Okuqina | I-Elastic Modulus KN//mm2 | I-Chemistry% | ||||||||||||||||||

| °C | N/mm2 | RT°C | 100°C | 200°C | 300°C | 400°C | 500°C | 600°C | C | Si | Mn | P | S | Cr | Ni | Abanye | ||||||

| I-T8A SK85 | -50 ukuze +100 | 1200-1800 | 206 | 202 | - | - | - | - | - | 0.80-0.09 | ≤ 0.35 | ≤ 0.50 | ≤ 0.03 | ≤ 0.03 | ≤ 0.20 | ≤ 0.25 | Cu≤0.30 | |||||

| 50CrV4 SUP10 | -50 ukuze +200 | 1200-1800 | 206 | 202 | 196 | - | - | - | - | 0.47-0.55 | ≤ 0.4 | 0.71.1 | ≤ 0.025 | 0.025 | 0.9 1.2 | ≤ 0.4 | V:0.1 0.25I-Mo≤ 0.1 | |||||

| C75 | -50 ukuze +100 | 1200-1800 | 206 | 202 | - | - | - | - | - | 0.70-0,80 | 0.15-0.35 | 0.60 0.90 | ≤ 0.025 | 0.025 | ≤ 0.4 | ≤ 0.4 | I-Mo≤ 0.1 | |||||

| 60Si2Mn SUP6 | -50 ukuze +200 | 1200-1800 | 206 | 202 | 196 | - | - | - | - | 0.56-0.64 | 1.50-2.0 | 0.6 0.9 | ≤ 0.035 | 0.035 | ≤ 0.35 | ≤ 0.35 | ||||||

| I-X 10CrNi 18-8 SUS301 | -200 ukuze +200 | 1150-1500 | 190 | 186 | 180 | - | - | - | - | 0.05-0.15 | ≤ 2.0 | ≤ 2.0 | ≤ 0.045 | 0.015 | 16.0 19.0 | 6.0 9.5 | I-Mo≤ 0.08 | |||||

| I-X 5CrNi 18-10SUS304 | -200 ukuze +200 | 1000-1500 | 185 | 179 | 171 | - | - | - | - | ≤ 0.07 | ≤ 1.0 | ≤ 2.0 | ≤ 0.045 | 0.015 | 17.0 19.5 | 6.0 9.5 | N≤ 0.11 | |||||

| I-X 5CrNiMo 17-12-2 SUS316 | -200 ukuze +200 | 1000-1500 | 180 | 176 | 171 | - | - | - | - | ≤ 0.07 | ≤ 1.0 | ≤ 2.0 | ≤ 0.045 | 0.015 | 16.5-18.5 | 10.0 13.0 | Mo:2.0-2.5N≤ 0.11 | |||||

| X 7CrNiAl 17-7 SUS631 | -200 ukuze +300 | 1150-1700 | 195 | 190 | 180 | 171 | - | - | - | ≤ 0.09 | ≤ 0.7 | ≤ 1.0 | ≤ 0.04 | 0.015 | 16.0 18.0 | 6.5 7.8 | Al:0.7-1.5 | |||||

| I-X5CrNiCuNb 16-4 SUS630 | -200 ukuze +300 | 1150-1700 | 195 | 190 | 180 | 171 | - | - | - | ≤ 0.07 | ≤ 1.0 | ≤ 1.0 | ≤ 0.035 | 0.03 | 15.0 17.0 | 3.0 5.0 | ||||||

| I-X8CrNiMoAl 15-7-2 | -200 ukuze +300 | 1150-1700 | 195 | 190 | 180 | 171 | - | - | - | ≤ 0.09 | ≤ 1.0 | ≤ 1.0 | ≤ 0.04 | 0.03 | 14.0 16.0 | 6.5 7.75 | Mo:2.0-3.0Al:0.75-1.5 | |||||

| Insimbi I-X39CrMo 17-1 | -50 ukuze +400 | 1200-1400 | 215 | 212 | 205 | 200 | 190 | - | - | 0.33-0.45 | ≤ 1.0 | ≤ 1.5 | ≤ 0.04 | 0.03 | 15.5 17.5 | ≤ 1.0 | Mo:0.7-1.3 | |||||

| X 22CrMoV 12-1 | -50 ukuze +500 | 1200-1400 | 216 | 209 | 200 | 190 | 179 | 167 | - | 0.18-0.24 | ≤ 0.5 | 0.4 0.9 | ≤ 0.025 | 0.015 | 11 12.5 | 0.3-0.8 | V:0.25-0.35Mo:0.8-1.2 | |||||

| X30WCRV53 SKD4 | -50 ukuze +500 | ≥ 1470 | 216 | 209 | 200 | 190 | 179 | 167 | - | 0.25-0.35 | 0.15-0.30 | 0.20 0.40 | ≤ 0.035 | 0.035 | 2.2 2.5 | ≤ 0.35 | V:0.5-0.7 W: 4-5 | |||||

| X40CrMoV5-1 SKD61 | -150 ukuze +600 | 1650-1990 | 206 | 200 | 196 | 189 | 186 | 158 | - | 0.32 0.40 | 0.8 1.20 | 0.20 0.50 | ≤ 0.030 | 0.030 | 4.75 5.50 | V:0.80-1.20Mo:1.1-.75 | ||||||

| I-Nickel I-Inconel X750 | -200 ukuze +600 | ≥ 1170 | 214 | 207 | 198 | 190 | 179 | 170 | 158 | ≤ 0.08 | ≤ 0.50 | ≤ 1.0 | ≤ 0.02 | 0.015 | 14.0 17.0 | ≥ 70 | Co≤ 1.0 Ti2.25-2.75 Fe 5.0-9.0 | |||||

| I-Inconel X718 | -200 ukuze +600 | ≥ 1240 | 199 | 195 | 190 | 185 | 179 | 174 | 167 | 0.02 0.08 | ≤ 0.35 | ≤ 0.35 | ≤ 0.015 | 0.015 | 17.0 21.0 | 50.0 55.0 | I-V≤ 1.0Mo:0.70-1.15 | |||||

| I-Nimonic 90 | -200 ukuze +700 | ≥ 1100 | 220 | 216 | 208 | 202 | 193 | 187 | 178 | ≤ 0.13 | ≤ 1.0 | ≤ 1.0 | ≤ 0.03 | 0.015 | 18.0 21.0 | U-Bal | V15.0-21.0Mo:2.0-3.0 I-Al≤ 0.2 | |||||

♦♦♦ Izici Zezinto Zokusebenza Zentwasahlobo Yokushisa Okuphezulu: ♦♦♦

♦ 304 insimbi engagqwali

I-304 insimbi engagqwali ikhubazekile ngenxa yokusebenza okubandayo ukuze ithuthukise izakhiwo zayo ezinwebekayo.Ayikwazi ukwenziwa lukhuni ukwelashwa ngokushisa.Izokhiqiza i-magnetism ngesikhathi sokusebenza okubandayo.I-304 insimbi engagqwali inokumelana nokugqwala okuqinile kanye nezakhiwo ezinhle zomzimba.

Insimbi engagqwali engu-316 yonakaliswa ukusebenza okubandayo ukuze ithuthukise izakhiwo zayo ezinwebekayo, futhi ayikwazi ukwenziwa lukhuni ngokwelashwa kokushisa.Izokhiqiza i-magnetism ngesikhathi sokusebenza okubandayo.Insimbi engagqwali engu-316 iqukethe i-molybdenum, enokumelana nokugqwala okuqinile kunensimbi engagqwali engama-304, futhi ingamelana nokugqwala ekusetshenzisweni kwamakhemikhali.

17-7PH ukumelana nokugqwala okufanayo ku-304 insimbi engagqwali, engancishiswa ukwelashwa kokushisa nokuqina kwemvula.Inokuqina okuphezulu namandla esivuno.Ukusebenza kokukhathala kungcono kunensimbi engagqwali engama-304 nensimbi ye-carbon engu-65Mn.Iphinde ibe nokunwebeka okuhle ngaphansi kwemvelo engu-℃.

♦I-15-7Mo (GH632, 0Cr15Ni7Mo2Al)

15-7MoHas ukumelana nokugqwala okufanayo ku-316 insimbi engagqwali.Ingabangelwa ukwelashwa kokushisa kanye nokuqina kwemvula.Inamandla aphezulu futhi ikhiqiza amandla, futhi ukusebenza kwayo kokukhathala kungcono kunensimbi engagqwali engu-316 kanye ne-65Mn carbon steel.Iphinde ibe nokunwebeka okuhle ngaphansi kwemvelo engu-℃.

I-Inconel X-750 iyi-nickel-based precipitation hardening deformation superalloy.Ngokuyinhloko isebenzisa i-r'phase njengesigaba sokuqina kwemvula yokuguga.Izinga lokushisa elinconywayo lingaphansi kuka-540℃.I-alloy inokumelana nokugqwala okuthile nokumelana ne-oxidation, futhi inokusebenza okuthile okuphansi kwezinga lokushisa.

I-Inconel 718 iyi-nickel-based precipitation hardening deformation superalloy.Izinga lokushisa elinconyiwe lingu -253--600℃.I-alloy inamandla aphezulu angaphansi kuka-600 ° C, inokumelana nokukhathala okuhle, ukumelana nemisebe, ukumelana ne-oxidation nokumelana nokugqwala, kanye nokusebenza kahle kokucubungula kanye nokuzinza kwesakhiwo sesikhathi eside.

I-alloy A-286 iwumthombo we-iron-based precipitation ukuwohloka kokuqina kwengxube ye-high-temperature.Izinga lokushisa elinconywayo lokusebenza lingaphansi kuka-540℃.I-alloy inamandla okushisa aphezulu naphansi kanye nokuzinza kwesikhathi eside, ukumelana nokugqwala okuhle nokusebenza kwe-thermal deformation, futhi ine-plasticity enhle yokucubungula nokusebenza okwanelisayo kwe-welding.