I-MONEL Alloy K-500 (UNS N05500/ WR2.4375) iyingxubevange ye-nickel-copper ehlanganisa izinzuzo zokumelana nokugqwala okuhle kakhulu okunamandla amakhulu nobulukhuni be-MONEL alloy 400. I-Aluminium ne-titanium yengezwe kusisekelo se-nickel-copper futhi yafudumala ngaphansi kwezimo ezilawulwayo ukuze kuncishiswe izinhlayiya ezincane ze-Ni3(Ti, AI) kuso sonke isisekelo se-nickel-copper, ngaleyo ndlela kuthuthukiswe i-matrix yokusebenza.Ukusetshenziswa komsebenzi oshisayo ukuze kuzuzwe umphumela wemvula ngokuvamile kubizwa ngokuthi ukuguga ukuqina noma ukuguga.

Ukusetshenziswa okujwayelekile kwemikhiqizo ye-MONEL alloy K-500 amaketango nezixhumi zekhebula neziphethu.

Izinsizakalo Zasolwandle: Imihlangano yamaphampu namavalvu,

Ukwelashwa kwamakhemikhali: ukucutshungulwa kwe-pulp ekukhiqizeni iphepha lama-blades odokotela nama-scrapers;

Ukumba imithombo kawoyela kanye nezinsimbi, i-pump shaft kanye ne-impeller, izindlu ezingenamagnetic, ukuphakama kokuphepha kanye ne-valve kawoyela kanye nokukhiqizwa kwegesi yemvelo;Nezinzwa nezinye izingxenye zemishini kagesi.

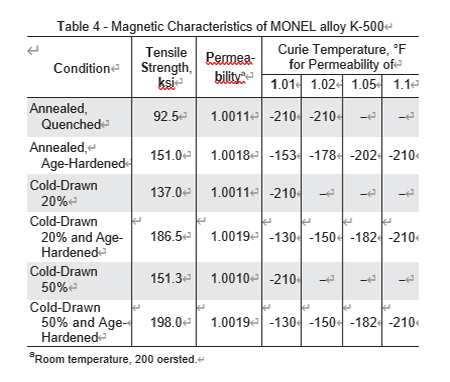

Enye yezakhiwo ze-Monel K500 alloy ukuthi cishe ayiyona i-magnetic, ngisho namazinga okushisa aphansi kakhulu.Nokho, kungenzeka ukwakha isendlalelo kazibuthe ebusweni bezinto ngesikhathi sokucubungula.I-Aluminiyamu nethusi kungafakwa i-oxyd ngokukhetha ngesikhathi sokushisisa, kushiye ifilimu enozibuthe ene-nickel ecebile ngaphandle kweshidi.Lo mphumela ugqama kakhulu ocingweni oluncane noma umucu onesilinganiso esiphezulu sobuso nesisindo.Ifilimu kazibuthe isuswa ngokukhethwa noma i-acid leaching ekhanyayo ukuze kubuyiselwe izinto ezingezona kazibuthe zezinto.Inhlanganisela yokungena okuphansi, amandla aphezulu, nokumelana nokugqwala okuhle kakhulu kusetshenziswe ezinhlelweni eziningi, ikakhulukazi okokusebenza kokulinganisa kahle nezinto zikagesi.

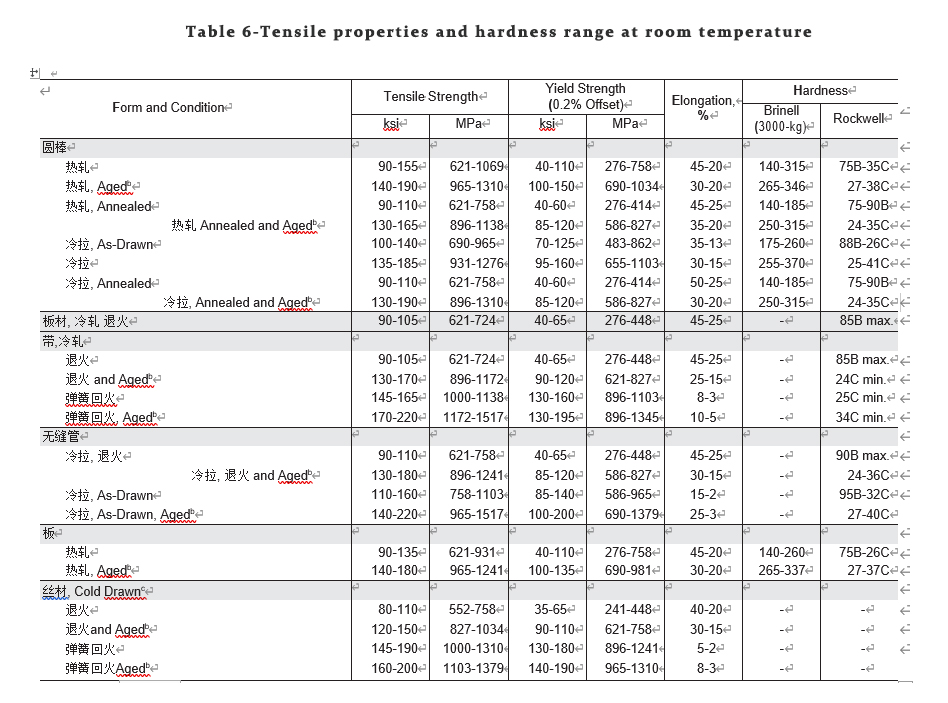

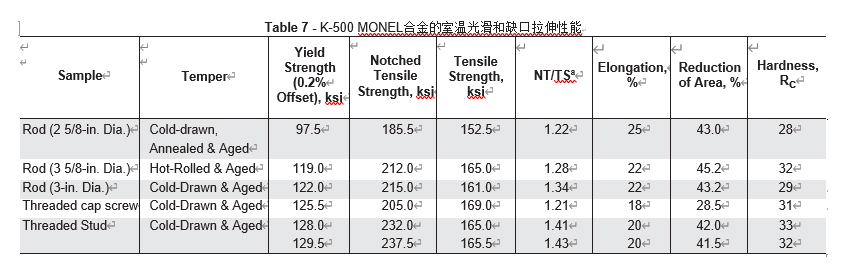

Kutholwe ukuthi i-Monel alloy K-500 inokuqina okuhle kakhulu kobukhulu ekuhlolweni kokuchayeka isikhathi eside nokuhlolwa kokujikeleza.Le mpahla ye-alloy ivumela ukuthi isetshenziswe kumishini yokunemba okuphezulu njenge-gyros.Ububanzi obuncane bezakhiwo eziqinile kanye nobulukhuni ezingeni lokushisa legumbi kukhonjisiwe kuThebula 6. Ubudlelwano obuseduze phakathi kwezakhiwo eziqinile kanye nobulukhuni bemigoqo kanye nokubumba buvela ku-Fig.4 kanye no-5, kanye nobudlelwano obufanayo bamashidi nemicu buvela kuMfanekiso 6. Ithebula lesi-7 liqhathanisa ukusebenza kwenotshi kwezifanekiso ezibushelelezi.Isikhathi esifushane kanye nezindawo zokushisa eziphakeme zokushisa ze-K500 alloy bar ngaphansi kwezimo ezihlukahlukene ziboniswa esithombeni esingezansi.Izinduku ezigoqiwe ezishisayo zihlolwe ngesivinini esingu-0.016 amayintshi/min ngokusebenzisa amandla esivuno kanye namayintshi angu-0.026/min ukusuka lapho ukuze kuphuke.Ama-specimens adonswa ngokubanda ahlolwe ngamandla esivuno angu-0.00075 amayintshi/min, alandelwa ngu-0.075 amayintshi/min.

I-K-500 Monel alloy inokusebenza okuhle kakhulu kwezinga lokushisa eliphansi.Amandla aqinile namandla esivuno akhuphuka ngokuncipha kwezinga lokushisa, kuyilapho ipulasitiki nokuqina cishe akuthinteki.Ngisho nasemazingeni okushisa aphansi njenge-hydrogen ewuketshezi, uguquko olusuka kolukhuni luye kolubi alwenzeki.Ngakho-ke, i-alloy ifanele izicelo eziningi zokushisa eziphansi.Ukusebenza kwe-K-500 alloy base metal kanye neshidi lensimbi elishiselwe ku -423°F kuyaboniswa.Uma ukwelashwa kokuguga kwenziwa ngemva kokuthungatha impahla yokushisela, i-weld enamandla okuguga eqinile yensimbi eyisisekelo ngaphandle kokulahlekelwa okukhulu kwe-ductility ingatholakala.Ukushiselwa kwezinto eziqinile yobudala kufanele kugwenywe ngoba i-ductility yabo iyancipha kakhulu.

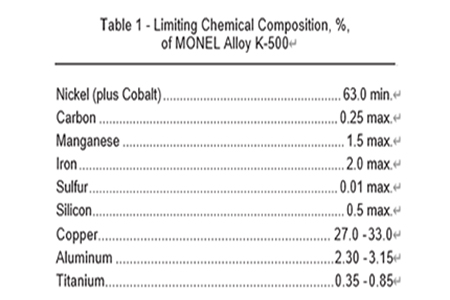

I-MONEL alloy K-500 iqokwe njenge-UNS N05500 kanye ne-Werkstoff NR.2.4375.Isohlwini lwe-NACEMR-01-75 Oil and Gas Services.Ingxubevange ye-K-500 itholakala ngezinhlobonhlobo zamafomu okugaya ajwayelekile okuhlanganisa ishubhu, ishubhu, ipuleti, isiqeshana, ipuleti, ibha eyindilinga, ibha eyisicaba, ama-forging, ihexagon nocingo.Ipuleti, Ishidi kanye Nomdweshu -BS3072NA18(Plate and strip),BS3073NA18(Strip),QQ-N-286(Plate, sheet and Strip),DIN 17750(Plate, Sheet and strip),ISO 6208(Ishidi, Ishidi kanye Nomucu) Amabha, Amabha, Izintambo kanye Nezimbobo -BS3075NA18(Intambo), BS3076NA18(Induku nenduku),ASTM B 865(Induku nenduku),DIN 17752(Induku nenduku),DIN 17753(Wire),DIN 17754(Forgings),QQ -N-286(Induku, Induku, Intambo Nezimbobo), SAE AMS 4676(Izinduku nezinduku),ASME Code Case 1192(Izinduku nezinduku),ISO 9723(izinduku),ISO 9724(Wire),ISO9725(Forgings) Amashubhu kanye namashubhu -BS3074NA18(Amashubhu namashubhu angenamthungo),DIN 17751(Amashubhu namashubhu) Eminye Imikhiqizo -DIN 17743(Chemical Composition),SAE AMS 4676(Chemical composition),QQ-N-286(Ukwakheka Kwekhemikhali)

Isikhathi sokuthumela: Sep-20-2022

- Olandelayo: Iqembu le-Sekonic Metals on Prevention and Control Epidemic

- Okwedlule: {Isingeniso somkhiqizo}N08020