Ifekthri yokukhiqiza umthombo we-Titanium mesh.I-Titanium wire mesh, i-Medical titanium mesh

Ifekthri yokukhiqiza umthombo we-Titanium mesh.I-Titanium wire mesh, i-Medical titanium mesh,

Ibanga lesi-2, Ibanga lesi-5, Ibanga le-11.Ibanga le-12.Ibanga le-16, Grade23, Ibanga lesi-7, Ibanga lesi-9, Ibanga, TA2, TAL, I-TC4,

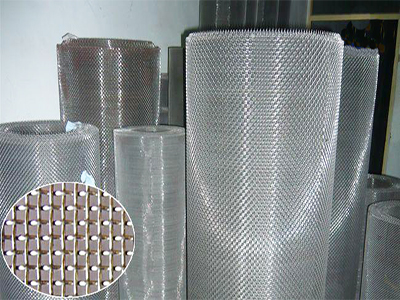

I-Titanium Mesh:I-Titanium Mesh eyenziwe yizintambo ze-Titanium Alloys, inkampani yethu ihlangene nefekthri ye-Mesh inweba uhla lomkhiqizo emikhiqizweni ye-mesh yezintambo neminye imikhiqizo eyenziwe.sineminyaka eminingi yokuhlangenwe nakho ekukhiqizeni i-wire mesh, futhi i-titanium mesh ekhiqizwayo inezici zokusebenza okuzinzile nokuhle kokuhlunga.

• Izinhlobo:

→ Imeshi ye-Plain weave → Inezikhala eziphothiwe

→ Imeshi yokuluka eboshwe ngaphambili → Imeshi ye-Dutch weave

• Ukucaciswa: I-1 mesh-100 mesh

Izindinganiso ze-ASTM ziyalandelwa ekukhiqizeni ama-wire meshes.Ukucaciswa kwe-mesh okutholakalayo kuyahluka ukusuka kokusindayo kuye kokuhle kakhulu.Imeshi esinda kakhulu yenziwe ngentambo engu-8.0mm kuyilapho inetha elihle kakhulu lenziwe ngentambo engu-0.03mm eno-360mesh/intshi.

• Izinhlelo zokusebenza:I-Titanium wire mesh ingasetshenziswa kwizihlungi ezimelana nokushisa okuphezulu, ukwakhiwa kwemikhumbi, ukukhiqizwa kwezempi, izihlungi zamakhemikhali, izihlungi zemishini, amanetha okuvikela ugesi, izihlungi zokukhipha usawoti emanzini olwandle, izihlungi zokushisa ezishisayo zikagesi ezishisayo, izihlungi zikawoyela, ukucubungula ukudla, ukuhlunga kwezokwelapha.

| I-Titanium Alloys Material Igama Elivamile | ||

| Gr1 | I-UNS R50250 | I-CP-Ti |

| Gr2 | UNS R50400 | I-CP-Ti |

| Gr4 | I-UNS R50700 | I-CP-Ti |

| Gr7 | I-UNS R52400 | I-Ti-0.20Pd |

| G9 | I-UNS R56320 | I-Ti-3AL-2.5V |

| G11 | I-UNS R52250 | I-Ti-0.15Pd |

| G12 | I-UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | I-UNS R52402 | I-Ti-0.05Pd |

| G23 | I-UNS R56407 | Ti-6Al-4V ELI |

♦ I-Titanium Alloys Chemical Composition ♦

| Ibanga | Ukwakheka kwamakhemikhali, iphesenti lesisindo (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Ezinye Izinto Ubukhulu.ngamunye | Ezinye Izinto Ubukhulu.ingqikithi | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5 6.75 | 3.5 4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 0.25 | - | 0.12 0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | - | - | - | - | 0.1 | 0.1 |

♦ Titanum Alloy Physical Properties ♦

| Ibanga | Izici ezingokomzimba | |||||

| Amandla aqinile Okuncane | Amandla esivuno Ubuncane (0.2%,i-offset) | I-Elongation ku-4D Ubuncane (%) | Ukuncishiswa Kwendawo Ubuncane (%) | |||

| ksi | I-MPa | ksi | I-MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |

I-Titanium mesh isetshenziselwa kakhulu ukuhlola izimo zemvelo ye-asidi, i-alkali nokuhlunga noma igesi, ukuhlunga uketshezi nokunye ukuhlukaniswa kwemidiya.Kunezindlela ezine ze-plain weave, i-twill weave, i-pre – crimp weave kanye ne-Dutch weave.Saikang Metal Technology Co., Ltd . uzibophezele ekuhlinzekeni amakhasimende ngemikhiqizo/izinkonzo ezisezingeni eliphezulu.Uma unentshisekelo ngemikhiqizo namasevisi ethu, sicela usithinte futhi ulindele impendulo yakho