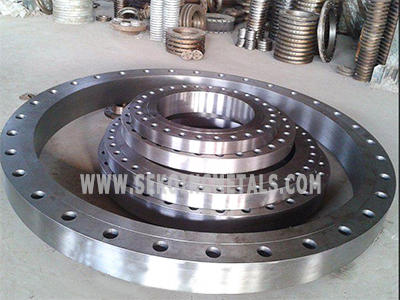

I-Incoloy 825 Flange

I-Incoloy 825 (W.Nr 2.4858) Flange

I-Flange Material :I-Incoloy Alloy 825 (UNS N08825)

Izinhlobo ze-Flange :Ngokusho kwezidingo zamaklayenti

Usuku lokuthumela :Izinsuku ezingu-15-30

Isikhathi Sokukhokha :T/T, L/C, Paypal, Ect

I-Sekoinc Metals Main ikhiqiza futhi inikeze ama-alloys akhethekile amaFlange, samukela isampula ye-oda

Ingxubevange 825Okuqukethwe kwe-nickel ephezulu kunikeza ingxubevange ephumelelayo yokumelana nokuqhekeka kwe-stress corrosion cracking.Ukumelana nokugqwala kuhle emithonjeni ehlukahlukene, njenge-sulfuric, phosphoric, nitric kanye ne-organic acid, izinsimbi ze-alkali ezifana ne-sodium hydroxide, i-potassium hydroxide ne-hydrochloric acid.

Ukusebenza okuphezulu okuphezulu kukonke kwe-Incoloy 825 kuboniswa kusincibilikisi senuzi esinemithombo yezindaba ebolayo ehlukahlukene, njenge-sulfuric acid, i-nitric acid ne-sodium hydroxide, konke kucutshungulwe endaweni efanayo.

| Ingxubevange | % | Ni | Cr | Mo | Fe | C | Mn | Si | S | Cu | Al | Ti | P |

| 825 | Okuncane. | 38.0 | 19.5 | 2.5 | 22.0 | - | - | - | - | 1.5 | 0.6 | - | |

| Ubukhulu. | 46.0 | 23.5 | 3.5 | - | 0.05 | 1.0 | 0.5 | 0.03 | 3.0 | 0.2 | 1.2 | 0.03 |

| Ukuminyana | 8.14 g/cm³ |

| Iphoyinti lokuncibilika | 1370-1400 ℃ |

| Isimo | Amandla aqinile Rm N/mm² | Amandla esivuno I-Rp 0. 2N/mm² | Ukwelula Njengo-% | Ukuqina kweBrinell HB |

| Ukwelashwa kwesixazululo | 550 | 220 | 30 | ≤200 |

• Izinhlobo ze-Flange :

→ I-Welding plate flange (PL) → I-Slip-on Neck Flange (SO)

→ I-Welding neck flange (WN) → Integral flange (IF)

→ I-socket welding flange (SW) → i-flange enemicu (Th)

→ I-flange ehlangene enqanyuliwe (LJF) → I-blind flange (BL(ama)

♦ Izinto Eziyinhloko Ze-Flange Esizikhiqizayo

• Insimbi engagqwali :I-ASTM A182

Ibanga F304 / F304L, F316/ F316L, F310, F309, F317L, F321, F904L, F347

I-Duplex Stainless Steel: Ibanga F44 / F45 / F51 / F53 / F55 / F61 / F60

• I-Nickel Alloys: ASTM B472, ASTM B564, ASTM B160

Imali engu-400,I-Nickel 200, Incoloy 825, Incoly 926, Inconel 601, Inconel 718

I-Hastelloy C276, i-Alloy 31, i-alloy 20, i-Inconel 625, i-Inconel 600

• I-Titanium Alloys:Gr1 / Gr2 / Gr3 /Gr4 / GR5/Gr7 /Gr9 /Gr11 / Gr12

♦ Amazinga:

ANSI B16.5 Class150,300,600,900,1500(WN,SO,BL,TH,LJ,SW)

I-DIN2573,2572,2631,2576,2632,2633,2543,2634,2545(PL,SO,WN,BL,TH)

I-Incoloy 825 Imikhiqizo Etholakalayo ku-Sekonic Metals

Kungani i-Incoloy 825?

I-825 alloy iwuhlobo lwe-alloy yobunjiniyela obujwayelekile, enokumelana nokugqwala kwe-asidi ne-alkali endaweni ye-oxidation kanye nokunciphisa kanye nokumelana ngokuphumelelayo nokuqhekeka kwe-corrosion ngenxa yokwakheka kwayo okuphezulu kwe-nickel.Kuzo zonke izinhlobo zemidiya, ukumelana nokugqwala kuhle kakhulu njengesibabule. i-asidi, i-phosphoric acid, i-nitric acid ne-organic acid, kuya ku-alkali, njenge-sodium hvdroxide, i-potassium hvdroxide nesisombululo se-hvdrochloric acid.Ukusebenza okuphelele okuphezulu kwe-825 alloy kubonisa kusincibilikisi esivuthayo se-nuclear se-corrosion medium ehlukahlukene, njenge-sulfuric acid, i-nitric acid ne-sodium hvdroxide konke kuphathwa ngendlela efanayo.

•Ukumelana kahle nokuqhekeka kwe-corrosion.

•Ukumelana kahle nokugqwala nokugqwala kwemigodi

•Ukumelana okuhle ne-oxidization kanye ne-non-oxidizing acid.

•Izakhiwo ezinhle zemishini ekamelweni lokushisa noma kufika ku-550 ℃

•Isitifiketi somkhumbi wokucindezela wokukhiqiza we-450 ℃

I-Incoloy 825 Inkambu yohlelo lokusebenza:

•Izingxenye ezinjengamakhoyili okushisa, amathangi, amakhreyithi, obhasikidi namaketanga ezitshalweni zokukha i-sulfuric acid

•Izishintshi zokushisa ezipholile emanzini olwandle, izinhlelo zamapayipi emikhiqizo yasolwandle;amashubhu kanye nezingxenye zesevisi yegesi emuncu

•Izishintshi zokushisa, izihwamuko, izihlikihli, amapayipi okucwilisa njll. ekukhiqizeni i-phosphoric acid

•Izishintshi zokushisa ezipholile emoyeni ezindaweni zokuhluza i-petroleum

•Ukucubungula ukudla

•Isitshalo samakhemikhali