I-AMS ASME ASTM yama-inconel625 alloy navigators

I-AMS ASME ASTM yama-inconel625 alloy navigators,

625 Alloy,Inconel 625 Bars,Inconel 625 Rods,Inconel 625 sheet,Inconel 625 plate,Inconel 625 strip,Inconel 625 coil,

Amagama Okuhweba Ajwayelekile: Inconel 625, UNS NO6625, Nickel Alloy 625, Alloy 625, Nickel 625, W.Nr.2.4856

I-Inconel Alloy 625 iyi-non-magnetic, i-corrosion resistant and oxidation, i-nickel-chromium alloy.Amandla aphezulu e-Inconel 625 awumphumela wokuqina kwenhlanganisela ye-molybdenum ne-niobium kusisekelo se-nickel chromium sengxubevange.I-Inconel 625 inokumelana okukhulu nezinhlobonhlobo zezindawo ezigqwalile ezingajwayelekile ezihlanganisa imiphumela yokushisa ephezulu efana ne-oxidation kanye ne-carburization.Amandla ayo avelele kanye nokuqina kumazinga okushisa asukela emazingeni okushisa e-cryogenic kuya kumazinga okushisa afika ku-2000° F (1093° C) asuselwe ikakhulukazi emiphumeleni yesixazululo esiqinile sezinsimbi eziphikisayo i-Columbium ne-molybdenum ku-matrix ye-nickel-chromium.

I-Inconel 625 Chemical Composition

| % | Ni | Cr | Fe | Mo | Nb+Ta | Co | C | Mn | Si | S | Al | Ti | P |

| Okuncane. | 58.0 | 20.0 | - | 8.0 | 3.15 | - | - | - | - | - | - | - | - |

| Ubukhulu. | - | 23.0 | 5.0 | 10.0 | 4.15 | 1.0 | 0.1 | 0.5 | 0.5 | 0.015 | 0.4 | 0.4 | 0.015 |

I-Inconel 625 Izakhiwo Zomzimba

| Ukuminyana | 8.4 g/cm³ |

| Iphoyinti lokuncibilika | 1290-1350 ℃

|

I-Inconel 625 Izakhiwo Zemishini Ejwayelekile

| Isimo | Amandla aqinile Rm N/mm² | Amandla esivuno I-Rp 0. 2N/mm² | Ukwelula Njengo-% | Ukuqina kweBrinell HB |

| Ukwelashwa kwesixazululo | 827 | 414 | 30 | ≤220 |

I-Inconel 625 Amazinga Nemininingwane

AMS 5599, AMS 5666, AMS 5837, ASME SB 443 Gr 1, ASME SB 446 Gr 1, ASTM B 443 Gr 1, ASTM B 446 Gr 1, EN 2.4856, ISO 15156-3, NACE M3R, NACE

I-UNS N06625, i-Werkstoff 2.4856

| Intambo | Ishidi | Hlikihla | Induku | Ipayipi | |

| I-AMS 5599, AMS 5666,AMS 5837, AMS 5979,ASTM B443 | I-ASTM B443 | I-AMS 5599, AMS 5979,ASTM B443 | I-ASTM B 446 SAE/AMS 5666, VdTÜV 499 | Ipayipi Elingenamthungo | Ipayipi elishiselwe |

| I-ASTM B 444/B 829 & ASME SB 444/SB 829SAE/AMS 5581 | ASTM B704/B751 ASME SB704/SB 751ASTM B705/B 775 , ASME SB 705/SB 775 | ||||

I-Inconel 625 Imikhiqizo Etholakalayo ku-Sekonic Metals

I-Inconel 625 Amabha nezinduku

Amabha ayindilinga/Amabha ayisicaba/amabha e-Hex, Usayizi Kusukela ku-8.0mm-320mm, Isetshenziselwa amabhawodi, izinsimbi nezinye izingxenye eziyisipele

I-Inconel 625 intambo yokushisela

Nikeza ngentambo yokushisela kanye ne-spring wire ngendlela yekhoyili futhi usike ubude.

I-Inconel 625 ishidi nepuleti

Ububanzi bufika ku-1500mm nobude bufika ku-6000mm, Ubukhulu busuka ku-0.1mm kuye ku-100mm.

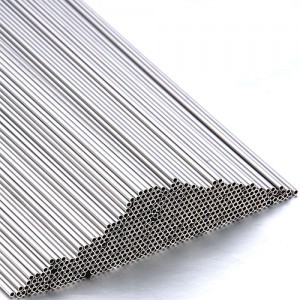

Ishubhu ye-Inconel 625 engenamthungo nepayipi elishiselwe

Usayizi wamazinga kanye nobukhulu obungokwezifiso kungakhiqizwa yithi ngokubekezelelana okuncane

I-Inconel 625 strip & coil

Isimo esithambile nesimo esiqinile esinendawo ekhanyayo engu-AB, ububanzi bufika ku-1000mm

I-Inconel 625 Fasteners

I-alloy 625 singanikela ngamabhawodi, amantongomane nezinye izinsimbi njengezidingo zamakhasimende

Izici ze-Inconel 625 :

1.Amandla aphezulu okukhasa

2.I-oxidation imelana no-1800°F

3.Ukumelana nokukhathala okuhle

4.Ukushisela okuhle kakhulu

5.Ukumelana okuvelele kokugoba kwe-chloride nokugqwala kwe-crevice

6.Amasosha omzimba ku-chloride ion stress corrosion cracking

7.Imelana namanzi olwandle ngaphansi kwezimo ezigelezayo nezimile futhi ngaphansi kokungcoliswa

Inkambu yesicelo ye-Inconel 625:

•Amasistimu okudonsa izindiza

•Amasistimu wokukhipha injini ye-jet

•Amasistimu e-thrust-reverser enjini

•Ama-Bellows namajoyinti okwandisa

•I-turbine shroud rings

•Izitaki ze-Flare

•Izingxenye zamanzi olwandle

•Imishini yenqubo yamakhemikhali ephatha ama-asidi axubile kokubili oxidizing kanye nokunciphisa.

Inkampani yethu Amafomu Emikhiqizo

Amabha & Izinduku

Inconel / Hastelloy/Monel/Haynes 25/ Titanium

I-Seamless Tube & Welded Tube

Amashubhu e-Nickel/ Titanium Alloy, i-U-goba / ishubhu yokushintsha ukushisa

I-Bolt & Nuts

Inconel 601/ Hastelloy C22/Inconel x750/Inconel 625 ect

Ishidi & Izingcwecwe

I-Hastelloy/Inconel/Incoloy/Cobalt/Tianium

I-Strip & Foil

I-Hastelloy/Inconel/ invar/ Ama-alloys athambile azibuthe ect

High Temperature Springs

Inconel 718/Inconel x750/ Nimonic 80A

Ucingo & Welding

I-Cobalt Alloy wire, i-Nickel alloy wire, i-Tianium Alloy wire

I-Special Alloy Flanges

I-Monel 400/ Hastelloy C276/ Inconel 718/ Titanium

I-Oil Tube Hanger

Inconel x750/ Inconel 718 /Monel 400 ect

I-Nickel Based Alloys

Izinto zokushisela

I-Cobalt Based Alloys

Izinsimbi Ezikhethekile Ezingenasici

I-Precision Alloys

I-Titanium Alloys

Ingabe ufuna ukufunda okwengeziwe noma uthole ikhotheshini?

Xhumana nathi

Iyiphi impahla eyenziwe nge-625 alloy?I-nickel - i-alloy esekelwe ene-Ni - Cr - Mo ephezulu.

Ukwakheka kwamakhemikhali kwe-Alloy 625: Chromium (Cr)20.0-23.0, Iron (Fe)< 5.0, (Al) & lt;0.4, Silicon (Si)< 0.50 manganese (Mn)< 0.50, Nickel (Ni)258, sulfur (S)< 0.015, Cobalt (Co)< 1.0,(Mo)8.0-10.0, Titanium (Ti)< 0.4, Phosphorus (P)< 0.015,(Nb) 3.15-4.15, Ikhabhoni (C)< 0.01.

I-625 Alloy ifaka i-oxidation enhle kakhulu nokumelana nokugqwala, amandla amahle kakhulu nokuqina, ukumelana nokukhathala okuhle kakhulu, ukwakheka okuphezulu, kanye nokushisela okuhle kakhulu.Ingakwazi ukugcina amandla nokuqina kwayo noma yikuphi ukusuka emazingeni okushisa aphansi kuya ku-2000°F.Ngenxa yokuqina okusheshayo kwe-alloy 625, inani elikhulu lokwakheka okubandayo lingadinga ukucwiliswa kulo lonke inqubo yokwakheka okubandayo.Ingxubevange ivame ukusetshenziswa ezinjinini zejethi nezinye izinhlelo zokusebenza ze-aerospace.