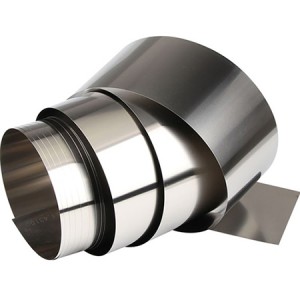

Ingxubevange 46 UNS K94600 ibha / ishidi/ strip

Amagama Okuhweba Ajwayelekile: I-alloy 46, 4J46, Fe-46Ni, UNS K94600, NiLo46

I-alloy 46 itholakala ebangeni elinikeziwe lethemu ngokulungisa okuqukethwe kwamandla angaphakathi e-nickel kanye ne-coefficient yokwandisa ye-softglass ehlukene ne-ceramic ehambisana nochungechunge lwe-alloy yokwandisa, i-coefficient yayo yokwandisa kanye nezinga lokushisa le-Curie liyakhuphuka ngokunyuka kokuqukethwe kwe-nickel. isetshenziswa kabanzi embonini ye-vacuum kagesi isakhiwo sokuvala impahla.

Ingxubevange 46 Chemical Ukubunjwa

| Ni | Fe | C | Cr | P | Si | Co | Mn | Al | S |

| 45.0~47.0 | U-Bal | ≤0.05 | ≤0.025 | ≤0.02 | ≤0.3 | - | ≤0.80 | ≤0.10 | ≤0.02 |

Isiqephu 46Ama-Constant ayisisekelo kanye ne-Mechanical Properties

| Ibhrendi | I-Thermal conductivity | Umthamo wokushisa othize | Ukuminyana | Iphoyinti lokuncibilika(℃) | Ukumelana nogesi | Iphuzu likaCurie |

| Isiqephu 46 | 14.7 | 502J | 8.18 | 1427 | 0.49 | 420 |

I-alloy 46 coefficient yokunwetshwa komugqa

| Ibanga | Ukwelashwa kokushisa kwamasampuli | I-coefficient emaphakathi yokunwetshwa komugqa | ||

| 20~300°C | 20~400°C | 20~500°C | ||

| Isiqephu 46 | Ukushisa ku-850~900°C endaweni evikelayo noma esimweni se-vacuum, bamba ihora elingu-1, bese upholisa ukuya ku-300℃ ngesilinganiso esingaphansi kuka-300℃/h. | 5.5~6.5 | 5.6~6.6 | 7.0~8.0 |

Amanothi:

1. Ubulukhuni be-Vickers bomugqa ohlanganisiwe (ishidi) akufanele bube ngaphezu kwe-170.

2. Ngomucu ongahlanganisiwe (ishidi) olethiwe, ngemva kokuphathwa ukushisa okungu-900℃, bese ubamba imizuzu engama-30, ubulukhuni be-Vickers akufanele bube ngaphezu kuka-170.

I-alloy 46 coefficient yokunwetshwa komugqa

| Ibanga | Isilinganiso se-coefficient yokunwetshwa komugqa kumazinga okushisa ahlukene, ā/(10-6/K) | |||||

| Isiqephu 46 | 20~100 ℃ | 20~200℃ | 20~300 ℃ | 20~400℃ | 20~500℃ | 20~600℃ |

| 6.8 | 6.5 | 6.4 | 6.4 | 7.9 | 9.3 | |

Ingxubevange 46 Mechanical Property

| Ibanga | Izinga lokushisa lokwelapha ukushisa, ℃ | Amandla okuqina, sb/MPa | I-Tensile stretch, δ(%) | Vickers ubulukhuni | Usayizi wokusanhlamvu |

| Isiqephu 46 | 750 | 527.5 | 34.8 | 137.4 | 7 |

| 850 | 510 | 35.4 | 134.6 | 6 | |

| 950 | 483.5 | 36.7 | 128.1 | 6~5 | |

| 1050 | 466.5 | 34.3 | 125.6 | 5~4 |

Ingxubevange 46 Impahla Magnetic

| Ibanga | ukungeniswa kukazibuthe | ukufakwa kwamagnetic okusalayo/ Br/T | ukuphoqa | i-perameability ephezulu | |

| Isiqephu 46 | B10/T | Bl00/T |

|

|

|

| 1.58 | 1.6l | 0.31 | 2.96 | 55.5 | |

I-alloy 46 Inkambu yohlelo lokusebenza:

I-alloy 46 isetshenziselwa ikakhulukazi ukunemba kwe-impedance diaphragm, ngesafire yokwenziwa, ingilazi ethambile, ukubekwa uphawu kobumba.