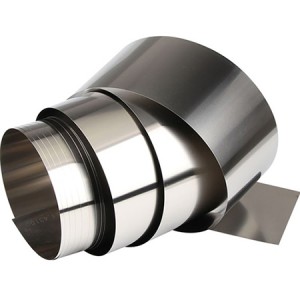

4J29-Kovar ingxubevange strip Ibha ye-Kovar/ishidi le-kovar/ithubhu le-kovar

Amagama Okuhweba Ajwayelekile:I-Kovar Alloy,4J29,UNS K94610(FeNi29Co17),29HК Kovar,KV-1,29HК-BИ,Werkstoff Nr.1.3981

Le alloy iphinde yakha i-Glass evaliwe futhi elawulwa ingxube yokunweba,Ingxubevange ine ai-coefficient yokunwetshwa komugqaefana naleyo ye-silicon boron ingilazi eqinile ku-20-450 ° C, aindawo ephakeme ye-Curie, kanye nokuzinza okuhle kwesakhiwo esinezinga lokushisa eliphansi.Ifilimu ye-oxide ye-alloy iminyene futhi ingaba kahlemanzi tengeingilazi.Ayihlanganisi ne-mercury futhi ilungele ukusetshenziswa kumamitha wokulahla aqukethe i-mercury.Yisakhiwo esiyinhloko sokuvala amadivaysi e-vacuum kagesi.

| C | Cr | Ni | Mo | Si | Mn | P | S | Fe | Co | Cu |

| ≤0.03 | ≤0.2 | 28.5-29.5 | ≤0.2 | ≤0.3 | ≤0.5 | ≤0.02 | ≤0.02 | ibhalansi | 16.8-17.8 | ≤0.2 |

| Ukuminyana(g/cm3) | I-Thermal conductivity(W/m·K) | Ukumelana nogesi(μΩ·cm) |

| 8.3 | 17 | 45 |

| Ingxubevange Amabanga

| Isilinganiso se-coefficient yomugqa wokwandisa a,10-6/ oC | |||||||

| 20-200 oC | 20-300 oC | 20-400 oC | 20-450 oC | 20-500 oC | 20-600 oC | 20-700 oC | 20-800 oC | |

| kovar | 5.9 | 5.3 | 5.1 | 5.3 | 6.2 | 7.8 | 9.2 | 10.2 |

I-Kovar isilinganiso se-coefficient yomugqa wokunweba emgqeni

| Ingxubevange Amabanga | Isistimu yokwelapha ukushisa kwesampula | Isilinganiso se-coefficient yomugqa wokunweba α,10-6/ oC | ||

| Kovar | 20-300 oC | 20-400 oC | 20-450 oC | |

| Emkhathini we-hydrogen ishiselwe ku-900 ± 20 oC, ukwahlukanisa i-1h, bese ishisiselwe ku-1100 ± 20 oC, ukwahlukanisa okungu-15min, kungabi ngaphezu kuka-5 oC / min izinga lokupholisa libe ngaphansi kuka-200 oC likhishwe. | ----- | 4.6-5.2 | 5.1-5.5 | |

I-Kovar ejwayelekile yokwandisa i-coefficient

| Ingxubevange Amabanga | Isilinganiso se-coefficient yomugqa wokwandisa a,10-6/ oC | |||||||

| Kovar | 20-200oC | 20-300 oC | 20-400oC | 20-450oC | 20-500oC | 20-600oC | 20-700oC | 20-800oC |

| 5.9 | 5.3 | 5.1 | 5.3 | 6.2 | 7.8 | 9.2 | 10.2 | |

I-Kovar Alloy Imikhiqizo Etholakalayo ku-Sekonic Metals

Kungani Inconnel Kovar?

I-1.I-Kovar isetshenziswa kabanzi embonini yezogesi, njengezingxenye zensimbi eziboshelwe ezimvilophini zengilazi eqinile.Lezi zingxenye zisetshenziselwa amadivaysi anjengamashubhu kagesi namashubhu e-X-ray, njll.

2.Embonini ye-semiconductor i-kovar isetshenziswa kumaphakeji avalwe nge-hermetically kuwo womabili amadivaysi esekethe adidiyelwe nahlukene.

I-3.Kovar inikezwa ngezindlela ezihlukahlukene ukuze kube lula ukukhiqizwa okuphumelelayo kwezingxenye ezihlukahlukene zensimbi.Inezici zokunweba ezishisayo ezifana nalezo zengilazi eqinile.Isetshenziselwa ukunwetshwa kwamalunga phakathi kwensimbi nengilazi noma izitsha zobumba.

I-4.Kovar alloy iyi-vacuum encibilikisiwe, i-iron-nickel-cobalt, i-alloy enwebekayo ephansi ukwakheka kwayo kwamakhemikhali kulawulwa ngaphakathi kwemikhawulo emincane ukuze kuqinisekiswe izici eziqondile ezifanayo zokunwetshwa kokushisa.Izilawuli zekhwalithi ezinabile zisetshenziswa ekwenziweni kwale alloy ukuze kuqinisekiswe izakhiwo ezifanayo ezingokomzimba nezomshini ukuze kube lula ekudwebeni okujulile, ukugxiviza kanye nokwenza imishini.

Inkambu yesicelo se-Kovar Alloy:

● Ingxubevange ye-Kovar isetshenziselwe ukwenza izimpawu ze-hermetic ngezingilazi ze-Pyrex eziqinile kanye nezinto zobumba.

●Le ngxubevange ithole ukusetshenziswa okubanzi kumashubhu kagesi, amashubhu e-microwave, ama-transistors nama-diode.Kumasekhethi ahlanganisiwe, isetshenziselwe iphakethe eliyisicaba kanye nephakheji ye-double-in-line.